A broader offer despite the stagnation

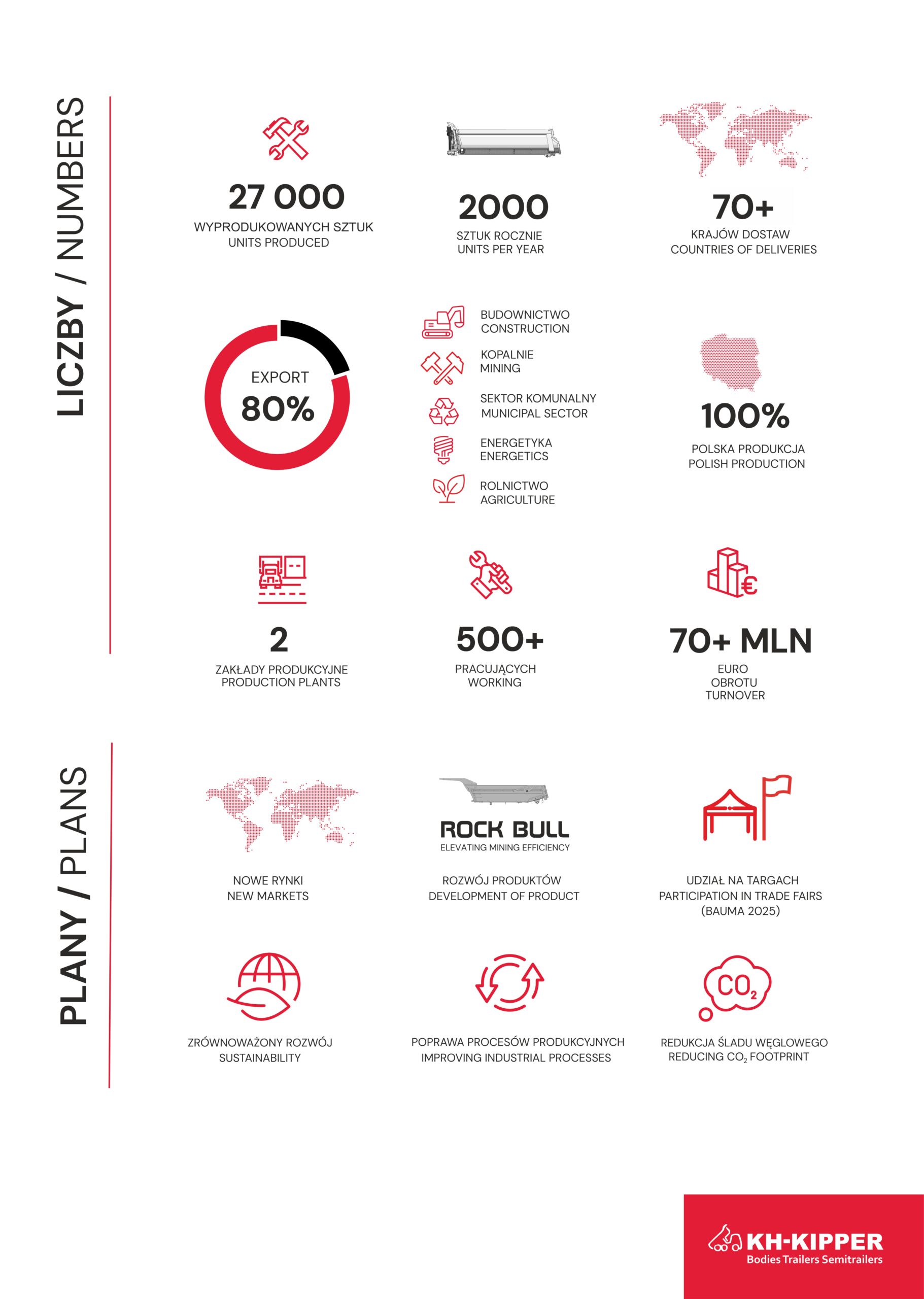

The economic situation in the truck market is not stopping KH-KIPPER from celebrating an important anniversary. Since the company was founded in 1997, 27,000 units have left its manufacturing facilities. Despite declines with most manufacturers on the market, 2024 was another year in which KH-KIPPER recorded its growth. Today, KH-KIPPER’s sales and service network includes dozens of outlets throughout Europe, which allow our customers get offers and support in the local language and in their area. KH-KIPPER bodies are manufactured exclusively in Poland, but their assembly on the chassis can also take place in the customer’s destination country without the need to transport the chassis to Poland.

The most important event of 2024 was the launch of KH-KIPPER’s latest product: the W1RB Rock Bull mine body. Its official branding is very symbolic. Strength, efficiency and durability are qualities without which no vehicle can survive in a mine. KH-KIPPER’s mission was clear: to increase the load capacity by at least 15%. After months of intensive work and direct feedback from users, the expectations were exceeded by achieving more than 16% higher load capacity compared to previous generations of tippers. Numerous design models were created, hundreds of computer simulations were carried out and extensive testing was performed in one of the most productive limestone quarries in Poland. The increased efficiency in transporting excavated material, which this product provides, is beneficial for both business optimisation and sustainable development. Tippers on a truck chassis help reduce CO2 emissions thanks to lower fuel consumption and the lightweight yet durable structure of the tipper body made of HARDOX 500 TUF steel. The vehicle uses cutting-edge digital technologies such as a vehicle performance monitoring system with data stored in the cloud and a reversing camera using artificial intelligence.

The Hanover IAA 2024 trade fair, where the Rock Bull was presented to the general public, is an indicator of the direction in which the European truck industry will be heading over the next few years. This year showed that the trend towards the electrification of heavy goods vehicles continues to be strong, despite the huge challenges users face in practice. KH-KIPPER has so far built more than 20 of such electric trucks, although so far mainly for customers in Norway.

The future of KH-KIPPER will be determined by the search for new markets and the pursuit of the intensive growth of the industry. This is to be helped by, among other things, investment in infrastructure. In 2024, the construction of a new building with a robotised load platform welding station was started to improve this process, and modern equipment was purchased for efficient sheet metal processing. The company’s plans for 2025 include a 3D laser automatic rack. The company’s successful growth in foreign markets is also supported by international promotion, which is why we are already extending our invitation to visit KH-KIPPER’s booth at the Bauma 2025 trade fair in Munich.